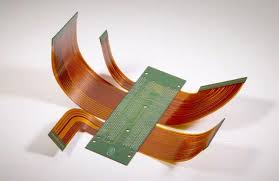

flex rigid pcb manufacturer facility hold

Safety is paramount in any manufacturing environment, especially in industries like flex rigid PCB manufacturing, where workers are exposed to various hazards associated with machinery, chemicals, and electrical equipment. Implementing essential safety precautions is crucial to protect workers from potential accidents and ensure a safe working environment. Here are some key safety precautions that are essential for flex rigid PCB manufacturers:

One of the most fundamental safety precautions is to ensure that all employees receive proper training and education regarding the potential hazards associated with flex rigid pcb manufacturer. Training should cover topics such as equipment operation, chemical handling, emergency procedures, and personal protective equipment (PPE) usage. By providing comprehensive training, manufacturers can empower workers to recognize and mitigate risks effectively.

The use of appropriate personal protective equipment is essential to minimize the risk of injury in flex rigid PCB manufacturing facilities. PPE may include items such as safety goggles, gloves, protective clothing, earplugs or earmuffs, and respiratory protection. Workers should be provided with the necessary PPE and instructed on its proper use to protect themselves from potential hazards, such as chemical exposure, electrical shock, or mechanical injuries.

What certifications does your flex rigid pcb manufacturer facility hold?

Ensuring the safety of machinery and equipment is critical to preventing accidents in flex rigid PCB manufacturing. Regular maintenance and inspection of equipment should be conducted to identify and address any potential hazards or malfunctions promptly. Safety features such as emergency stop buttons, machine guards, and interlocks should be installed and maintained to prevent accidental contact with moving parts or hazardous materials.

Flex rigid PCB manufacturing often involves the use of chemicals such as etchants, solvents, and adhesives, which can pose health and safety risks if not handled properly. Workers should be trained on safe chemical handling procedures, including proper storage, handling, and disposal practices. Chemicals should be stored in designated areas away from heat sources, incompatible materials, and ignition sources to minimize the risk of accidents or spills.

Ergonomic hazards, such as repetitive motion injuries and musculoskeletal disorders, are common in manufacturing environments and can impact worker health and safety. Employers should implement ergonomic principles to design workstations and processes that reduce physical strain and fatigue. This may include adjusting workstation heights, providing ergonomic tools and equipment, and implementing rotation schedules to vary tasks and reduce repetitive motions.

Being prepared for emergencies is essential to ensure the safety of workers in flex rigid PCB manufacturing facilities. Emergency response plans should be developed and communicated to all employees, outlining procedures for evacuations, medical emergencies, fires, chemical spills, and other potential hazards. Regular drills and training exercises should be conducted to familiarize workers with emergency procedures and ensure a swift and coordinated response in the event of an emergency.

Safety is an ongoing process that requires continuous monitoring and improvement. Manufacturers should regularly assess their safety procedures, identify areas for improvement, and implement corrective actions to address any deficiencies. Workers should be encouraged to report safety concerns or near-misses so that proactive measures can be taken to prevent accidents in the future.

In conclusion, implementing essential safety precautions is crucial to protect workers and create a safe working environment in flex rigid PCB manufacturing facilities. By prioritizing safety, manufacturers can mitigate risks, prevent accidents, and ensure the well-being of their employees while maintaining efficient and productive operations.